Rowan | Macromolecules

Effect of Graft Molecular Weight and Density on the Mechanical Properties of Polystyrene-Grafted Cellulose Nanocrystal Films

James H. Lettow, Han Yang, Paul F. Nealey*, and Stuart J. Rowan

Macromolecules

Publication Date:November 14, 2021

DOI: 10.1021/acs.macromol.1c01886

Abstract

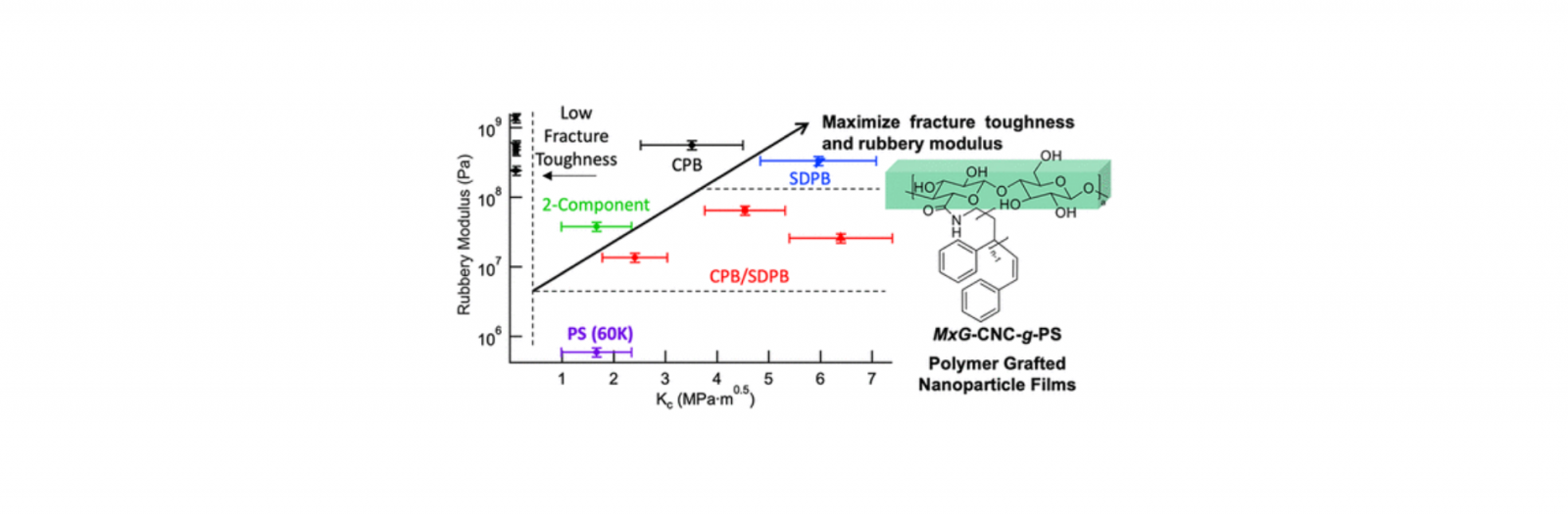

Polymer-grafted nanoparticle (PGN) films were prepared from polystyrene (PS) grafted to rodlike cellulose nanocrystals (MxG-CNC-g-PS) with a controllable grafting density (0.03–0.25 chains/nm2) and molecular weight (5–60 kg/mol). These nanorod-based PGNs are solution- and melt-processible, permitting access to one-component composite films with high nanofiller loadings (with up to 55 wt %). The impact of both grafted polymer density and molecular weight on the mechanical properties of the films was investigated and related to the polymer brush conformation: concentrated polymer brush (CPB), semidilute polymer brush (SDPB), or CPB core with SDPB corona (CPB/SDPB). The rubbery regime storage modulus (above Tg) showed 2 orders of magnitude increase, maximizing at a low degree of polymerization (N) and low grafting density (σ). Fracture toughness was maximized in samples with the grafted polymer in the SDPB or CPD/SDPB (higher N and relatively low σ) regime and showed enhancement relative to PS of molecular weight similar to the graft. In line with prior computation predictions, optimizing for both rubbery modulus and fracture toughness in such nanorod-based PGN films requires the polymers in the SDPB regime and CNC loading levels (ca. 50–60 wt %) that are difficult to attain in more traditional two-component CNC composites.